DESIGN FOR MANUFACTURING

Conceptual design to production intent/Rapid Prototyping

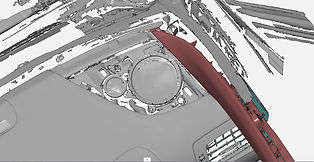

Conceptual design

Pre-development scan

Behind the scenes processing

-

Collection (scan) of actual data from real-world components ensures product being developed works.

-

Un-foreseen issues prior to product development may be found and worked through quicker.

-

Collect key elements for design and packaging.

-

The conceptual design stays true to the existing product.

Pre-development CAD

-

Scanned areas are converted to surface.

-

Expedites product faster especially when manufacturer CAD is unavailable.

-

Key in achieving a high degree of accuracy the first time minimizing benching time to fit the product.

-

Allows for faster conceptual development.

-

Easy to work with.

Industrial design/ concept developed from

reference CAD data

-

The Conceptual Design process is accelerated utilizing CAD developed from the scanned focus areas.

-

Surface (CAD) provides the best medium for product design and part integration.

Know the part(s)/assembly will work the first time

-

The design concept is taken and engineered for stack-up and fit-and-finish conditions.

-

Mounting and attachment methods work out.

-

Prototyping CAD built fitting actual structure.

-

Optimize ideas and concepts through CAD.

-

Prototypes made from CAD using assorted materials.

A collaborated effort

-

Final production prototype assembly model presented.

-

Design concept package brought to reality

-

Total of 10 IP / 15 ceiling / 12 pillar / 6 rear shelf parts and tools.

-

Faster production of art to part.